Catering to Brisbane's new entertainment precinct with comprehensive refrigeration solutions

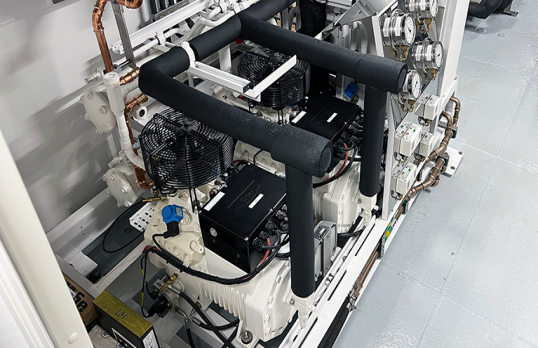

The Star Brisbane is part of Queen's Wharf, a whole new entertainment district on the banks of the Brisbane River. Food and drinks for its customers are kept fresh by cutting-edge refrigeration systems: BITZER Australia provided various maxi and mini racks with a total of 41 reciprocating compressors and 34 evaporators. BITZER electronic components such as IQ MODULES and VARISTEP capacity control ensure maximum efficiency and sustainability. The cooperation among the project partners ACTROL, BITZER, Ellis Air and Shelair was exceptionally close and successful.

Queen-s Wharf Brisbane is a newly built multipurpose entertainment and lifestyle precinct and anticipated to bring an additional 1.3 million tourists to the area each year. The multifaceted development includes a Sky Deck, new restaurants, a 1500-seat ballroom, hotels, shopping and entertainment locations.

The expansive project includes Brisbane's only casino, which replaced the Treasury Casino. The Star Brisbane relies on Australian-built refrigeration racks fitted with BITZER compressors for its catering equipment, cold rooms and beer systems. Via its partner Shelair, BITZER equipped 27 cool rooms and freezer rooms, 63 remote refrigeration cabinets, three beer systems and two blast chillers.

Additionally, the delivery of equipment and the scheduled crane lifts led to supply challenges that needed to be managed. This successful management has resulted in high levels of customer satisfaction. ACTROL played a crucial role in this process by holding items and delivering them to the site as needed, using their national branch network.

A collaborative success

The refrigeration project posed many challenges, among them strict timelines and spatial limitations as well as requirements for top sustainability. Like most projects of this scope, it was a collaborative effort, with tier-one contractor Multiplex commissioning mechanical services contractor Ellis Air to provide the building component. BITZER's distribution partner ACTROL in turn supplied the refrigeration packages to refrigeration contractors Shelair and Ellis Air. This included the food and beverage packages, comprising multiple refrigeration and cold room systems, beer systems and post-mix systems. To meet this need, BITZER's sales and engineering team assisted ACTROL by supplying eleven low- and medium-temperature refrigeration racks as well as Buffalo Trident evaporators of different sizes and configurations.

ACTROL provided engineering support, carrying out thermal and system loads for the contractors and confirming that the consultants' requirements were met. ACTROL also assisted with the extensive pipework. Shelair completed Stage A and B1 of the installation, paying close attention to detail. The pipework was done with precision and careful planning. The electrics were clearly executed, and the commissioning was completed to a high standard. Pipework and water-cooled condenser flow controls and connections were all custom designed. Electrical, cold room and evaporator installation went smoothly.

Leadership in sustainability

The entire Queen's Wharf precinct is targeting a six-star Green Star rating, which means the project is being built to a world-leading standard for sustainability. To meet the strict sustainability targets, each BITZER maxi rack features an IQ MODULE mounted on the main compressor. The module controls and monitors the peripheral devices, records operating data and can be conveniently operated with the BEST SOFTWARE. It simplifies installation and system integration as well as compressor operation and service.

VARISTEP capacity control on the remote units provides precise compressor control and monitoring, saving energy when the compressor is outside normal operating parameters. Electronic expansion valves on the evaporators control refrigerant flow and ensure the system operates as accurately and efficiently as possible.

Supplying comprehensive service

Throughout the project, BITZER and its partners at ACTROL provided information to the consultant and mechanical contractor, for example specifying the space requirements for coordinating equipment in the utility and back-of-house areas. The BITZER engineering team ensured that the selected equipment and electrics were able to meet the complex project-specific design parameters.

Water-cooled condensers were required due to the location of machine rooms throughout the building. However, due to high static-head pressures, traditional shell and tube heat exchangers were not suitable. Instead, BITZER supplied high-pressure plate heat exchangers to meet the project requirements. The delivery of the equipment and the required dates for the crane lifts meant that there were time constraints on the delivery, which were met to the customer's satisfaction. ACTROL provided technical support to the contractors and ensured that the consultants' requirements were met. They assisted with the dimensioning of the pipework and held stock on-site for delivery to the site for crane lifts.

‘BITZER has supported Ellis Air at every stage of the project life cycle,’ says Matthew Raynham, Project Manager at Ellis Air. ‘ACTROL and BITZER helped with the design, before the installation contractor was appointed, and again when the Skydeck leases were let. Ellis Air ensured that the same level of quality was maintained throughout the fit-out.’

The Star Brisbane opened in August 2024, and BITZER has already secured the supply of refrigeration systems for the next project, the Star's new Sky Deck Part B1. The 250 m long Sky Deck will be a landmark destination, soaring 100 m above the Brisbane River with spectacular views from its restaurants and bars.

Approved and contribution by Destination Brisbane Consortium (DBC).

Contact us for further informationOverall, BITZER supplied the following components:

Medium-temperature systems with refrigerant R134a and

- Maxi rack with 3× 6FE compressors

- Maxi rack with 2× 4FE compressors

- Mini rack with 3× 4CES compressors

- Mini rack with 2× 4BES compressors

- Mini rack with 4× 4CES compressors

- Mini rack with 3× 4CES compressors

- Mini rack with 2× 4DES compressors

Low-temperature systems with refrigerant R404A and

- Maxi rack with 2× 6FE compressors

- Mini rack with 2× 4EES compressors

- Mini rack with 2× 4DES compressors

- Mini rack with 2× 4FES compressors

- Remote unit with 2× CES compressors

- Remote unit with 2× CES-4Y compressors

- Mini rack with 2× 4DES-7 compressors

Medium-temperature beer systems with refrigerant R134a and 3× remote units with 4× PES15 compressors with AC fans

- 38× GACC Buffalo Trident evaporators fitted with electronic expansion valves and compact fans for freezer and cold rooms.