Natural refrigerants at the Holzkirchen brewery site

König Ludwig Brauerei is keeping the House of Wittelsbach’s 760 years of brewing tradition alive. To future-proof the production processes at the Holzkirchen site in the foothills of the Bavarian Alps, an advanced cooling system went into operation in April 2023. The project was a collaboration between Rieger Kälteanlagenbau and the Munich team from Fischer Kälte-Klima. Three open-drive reciprocating compressors from BITZER are at the heart of the system.

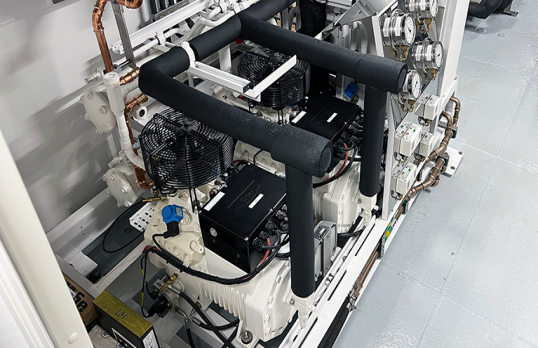

The structure of the old building meant it was not possible to lay ammonia pipes. A cold water network was installed instead. The system runs on the environmentally friendly refrigerant R723, which is a mixture of ammonia and dimethyl ether. Three open-drive 6-cylinder reciprocating compressors from BITZER ensure that the refrigeration system operates reliably. The compressors were optimised especially for refrigerants containing ammonia and boast minimal frictional losses, exceptional ease of maintenance and smooth operation, all whilst allowing for a compact system design.2023

The cooling energy is then distributed and supplied to the individual evaporators by a secondary circuit that acts as a brine-glycol circuit. This is where DH dry-expansion evaporators from BITZER come into play.

Project requirements:

- Modernisation of an ageing system

- Upcoming restrictions for the current refrigerant

With a new cooling system containing BITZER components and the environmentally friendly refrigerant R723, König Ludwig Brauerei has taken an important step towards sustainability. All project partners worked well together, which resulted in an efficient, reliable system that will safeguard the tradition and future of the brewery.

Contact us for further information