Switch off compressor, depressurize compressor and oil filter chamber and extract oil

WARNING

WARNINGThe oil filter chamber and the compressor are pressure chambers independent of each other!

The oil filter chamber and the compressor are pressure chambers independent of each other!

Serious injuries are possible.

For maintenance work, relieve separately the compressor and the oil filter chamber of pressure!

Wear safety goggles!

- Switch off the compressor which is being worked on, or the entire system, if necessary, and secure from being switched on again!

- Let the compressor cool down.

- Close valves (suction gas side, discharge gas side, Economiser, refrigerant injection, oil supply).

- Depressurize compressor.

- Depressurize the oil filter chamber separately! Then drain oil from the oil filter chamber.

- HS.85 and OSK85/OSN85:

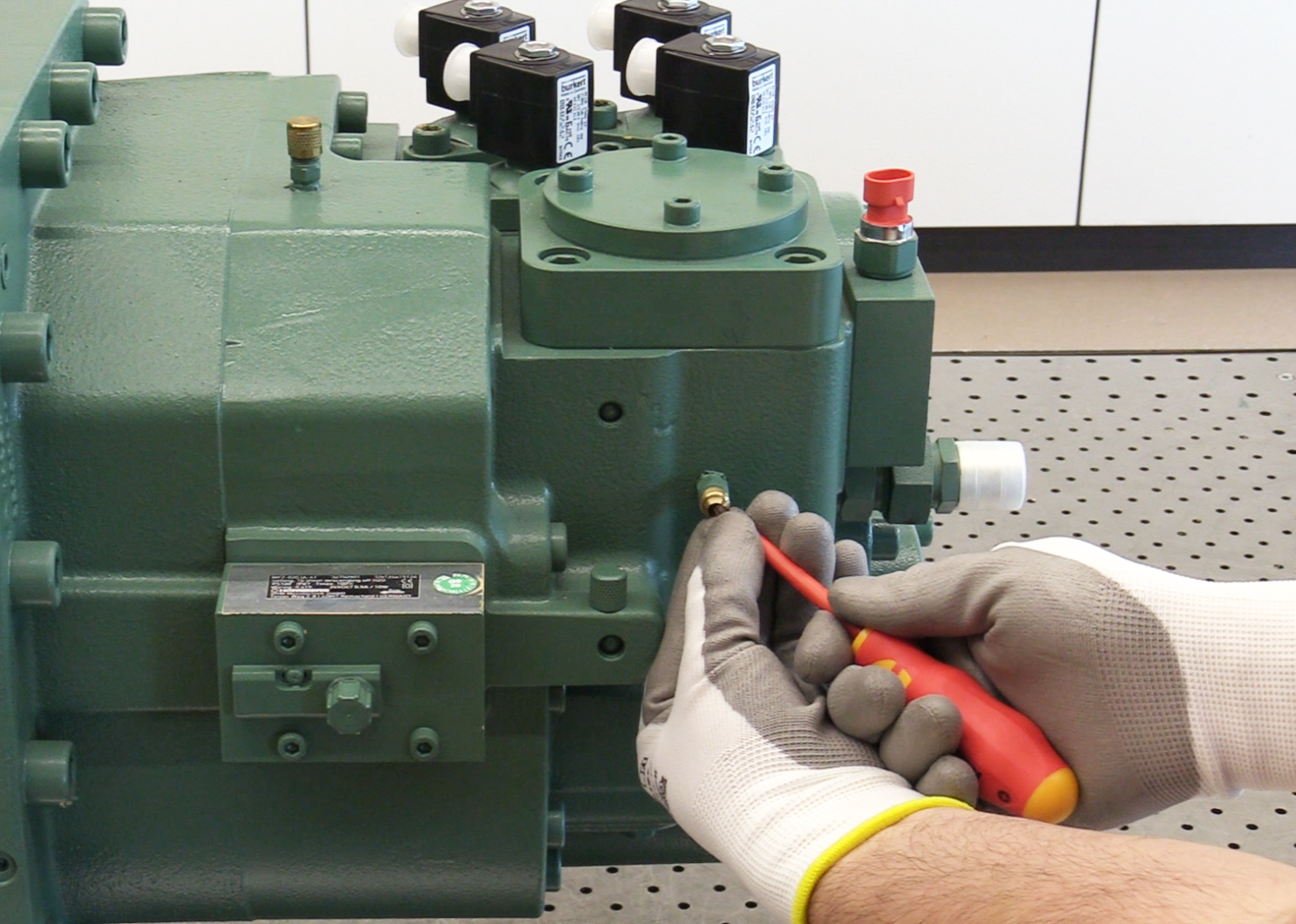

Release the pressure at the pressure relief of the oil filter chamber (see photo). Drain refrigerant/oil mixture into evacuated vessel..

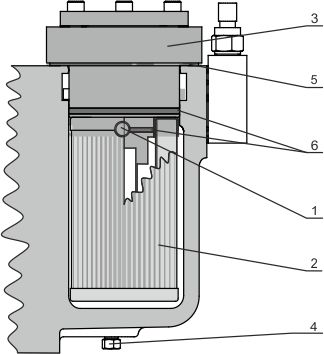

Drain oil at oil drain, position 4 (OSK85 and OSN85/HS.85: Oil filter chamber ) into vessel. - OSKA85/OSNA85:

Compressors for ammonia applications have a plug instead of a Schrader valve at the pressure relief of the oil filter chamber. However, they are equipped with a shut-off valve at the oil inlet. In order to release the pressure in the oil filter chamber, connect an additional line with integrated shut-off device to the service connection of the valve – valve spindle must be in back position. Close the oil shut-off valve and then use the service connection at the valve to drain oil/refrigerant mixture into evacuated vessel.

Drain oil at oil drain, position 4 (OSK85 and OSN85/HS.85: Oil filter chamber ) into vessel. - Store refrigerant/oil mixture and oil sealed and dispose properly!