Oil solenoid valve and oil stop valve

During standstill of the plant and with closed oil solenoid valve or oil stop valve an oil flow must not be visible in the oil sight glass.

Oil solenoid valve: HS.53 .. HS.74, HS.95 and OS.53, OS.74, OS.95

- In case of a leaking valve check the diaphragm and the retaining ring regarding deformations.

- Max. height of retaining ring is 2.0 mm.

Inspection interval | Replacement interval |

|---|---|

5000 h, at least once a year | 100000 h |

Oil stop valve: HS.85 and OS.85

Inspection interval | Replacement interval |

|---|---|

5000 h, at least once a year | only in case of leakage |

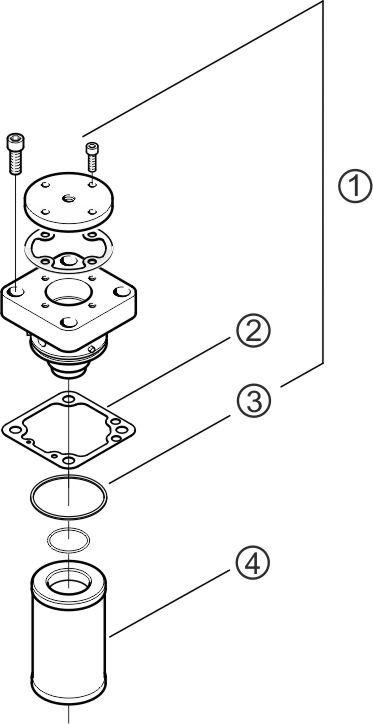

1 | Oil stop valve | 2 | Flat gasket |

3 | O ring | 4 | Oil filter |

- Check piston of oil stop valve for free movement and replace valve if necessary.

- Check oil filter.

- Ensure fitted flat gasket and O ring are new (Oil stop valve HS.85 and OS.85).

For detailed description of dismounting and mounting of oil stop valve see SB-110 (HS.85) and SB-510 (OS.85).

Possible reason for leakage:

- Hydraulic overload e. g. due to oil or refrigerant flooding of the compressor during standstill periods.