Inside the terminal box of compressor

Authorized staff

All work done on the products and the systems in which they are or will be installed may only be performed by qualified and authorised staff who have been trained and instructed in all work. The qualification and competence of the qualified staff must correspond to the local regulations and guidelines.

Mount SE-i1 inside terminal box

- Socket spanner TX20

Attach 3 clamp type cable lugs for phase monitoring to motor bolts

Pay attention to terminal assignment!

- Left pin → black cable

- Middle pin → brown cable

- Right pin → blue Kabel

Connect cable cores of PTC resistors for monitoring the motor winding temperature to terminals 8 and 9

- Screwdriver

- After mounting, check electrical cable connections for tightness!

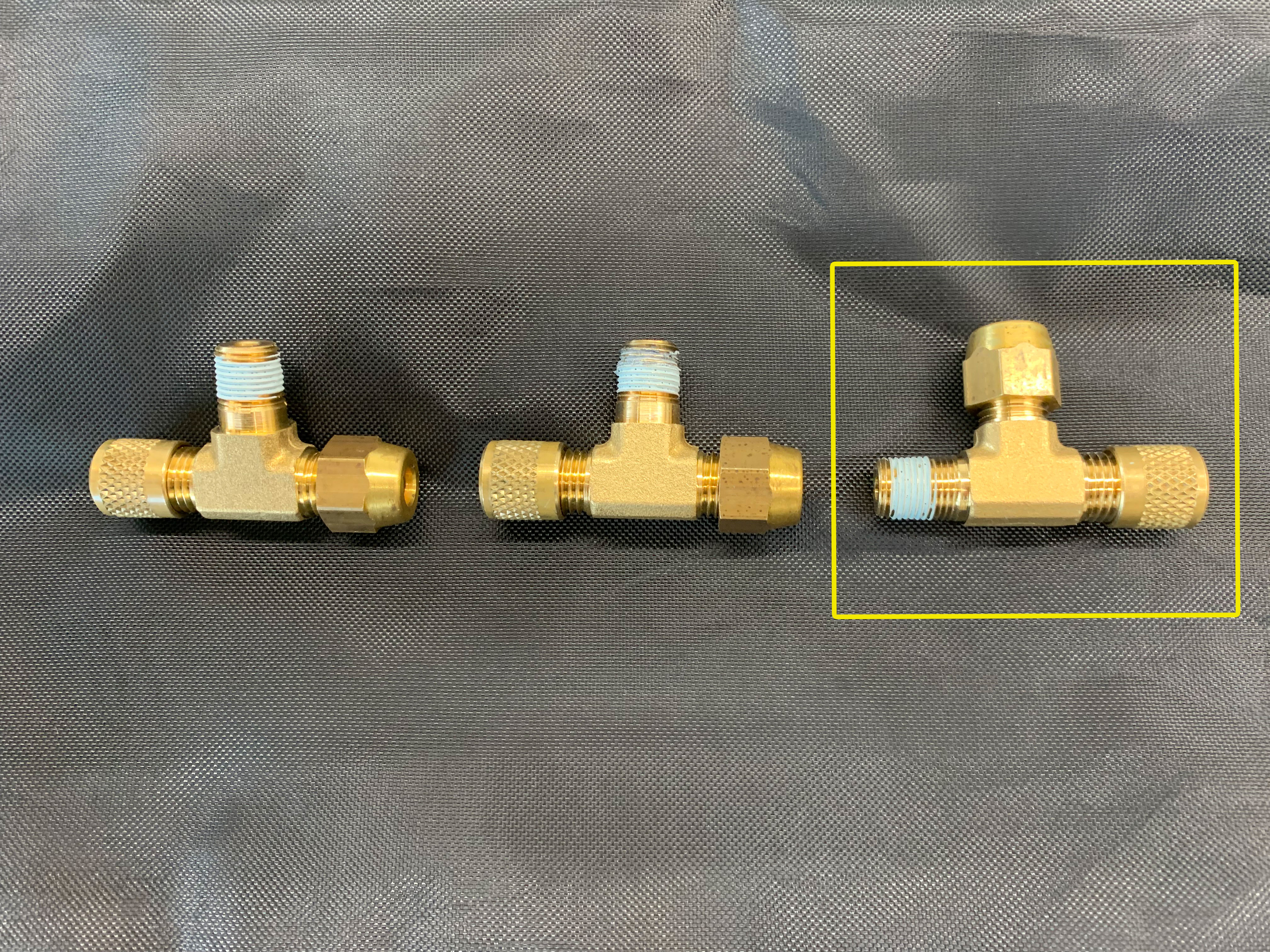

Attach T joint for mounting the high pressure transmitter

- Ring wrench / spanner SW 13

- Spanner SW 14

The connection positions for pressure transmitters at the CS. series vary depending on compressor size. The following videos show the positions for a CS.85 compressor.

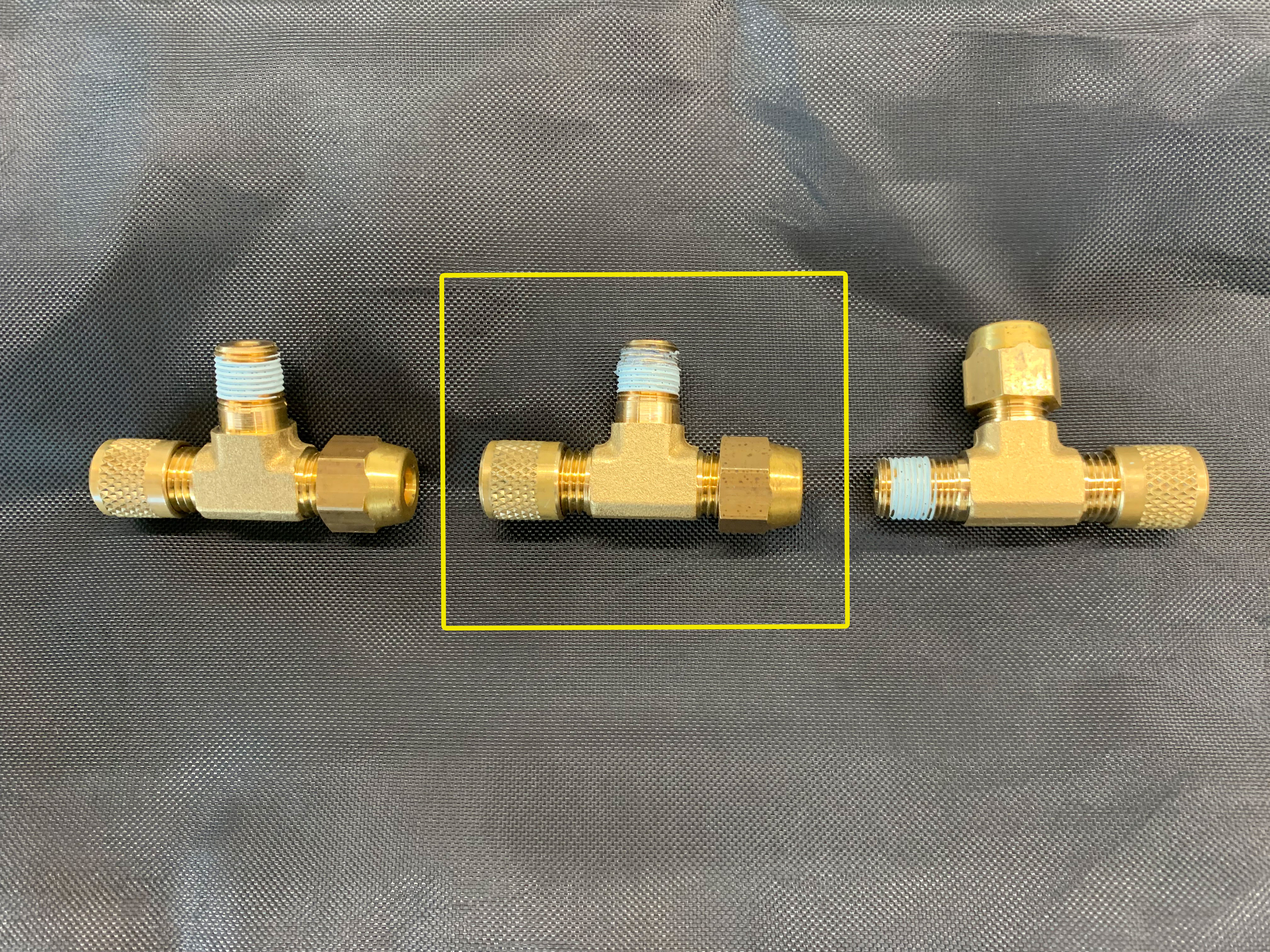

Attach T joint for mounting the low pressure transmitter

- Ring wrench / spanner SW 13

- Spanner SW 14

The connection positions for pressure transmitters at the CS. series vary depending on compressor size. The following videos show the positions for a CS.85 compressor.

Mount the low pressure transmitter

- Spanner SW 16 (counter-hold with spanner SW 14)

- Suitable refrigeration compressor oil

- Torque spanner

- Tightening torque: 35 Nm

Mount the high pressure transmitter

- Spanner SW 16 (counter-hold with spanner SW 14)

- Suitable refrigeration compressor oil

- Torque spanner

- Tightening torque: 35 Nm

Create a vacuum at the high pressure side (at least -0,5 bar)

This ensures that no oil leaks through the connection when the discharge gas temperature sensor gets replaced.

- Vacuum pump

Remove existing discharge gas temperature sensor (PTC) and install new discharge gas temperature sensor (NTC)

- Work quickly!

- Ratchet wrench with socket spanner size 17

Mount new discharge gas temperature sensor (NTC)

- Ratchet wrench with socket spanner size 17

- Torque spanner

- Tightening torque: 17 Nm

Switch off and remove vacuum pump

Open cable bushing at terminal box

- Screwdriver handle

Push through screwed cable gland

- Screwdriver

Guide all cables into terminal box

Connect cable cores of discharge gas temperature sensor (NTC) to terminals 12 and 13 of SE-i1

- Screwdriver

- Brown cable → terminal 12

- White cable → terminal 13

- After mounting, check electrical cable connections for tightness!

Connect cable cores of high pressure transmitter sensor to terminals 14, 15, 16 of SE-i1

- Screwdriver

- Cable 1 → Terminal 14

- Cable 3 → Terminal 15

- Cable 2 → Terminal 16

- After mounting, check electrical cable connections for tightness!

Connect cable cores of low pressure transmitter to terminals 17, 18, 19 of SE-i1

- Screwdriver

- Cable 1 → Terminal 17

- Cable 3 → Terminal 18

- Cable 2 → Terminal 19

- After mounting, check electrical cable connections for tightness!