Selection with the Bitzer Software

At present, the Bitzer Software offers calculations with frequency inverter only for Orbit compressors.

Step 1: Choosing the compressor

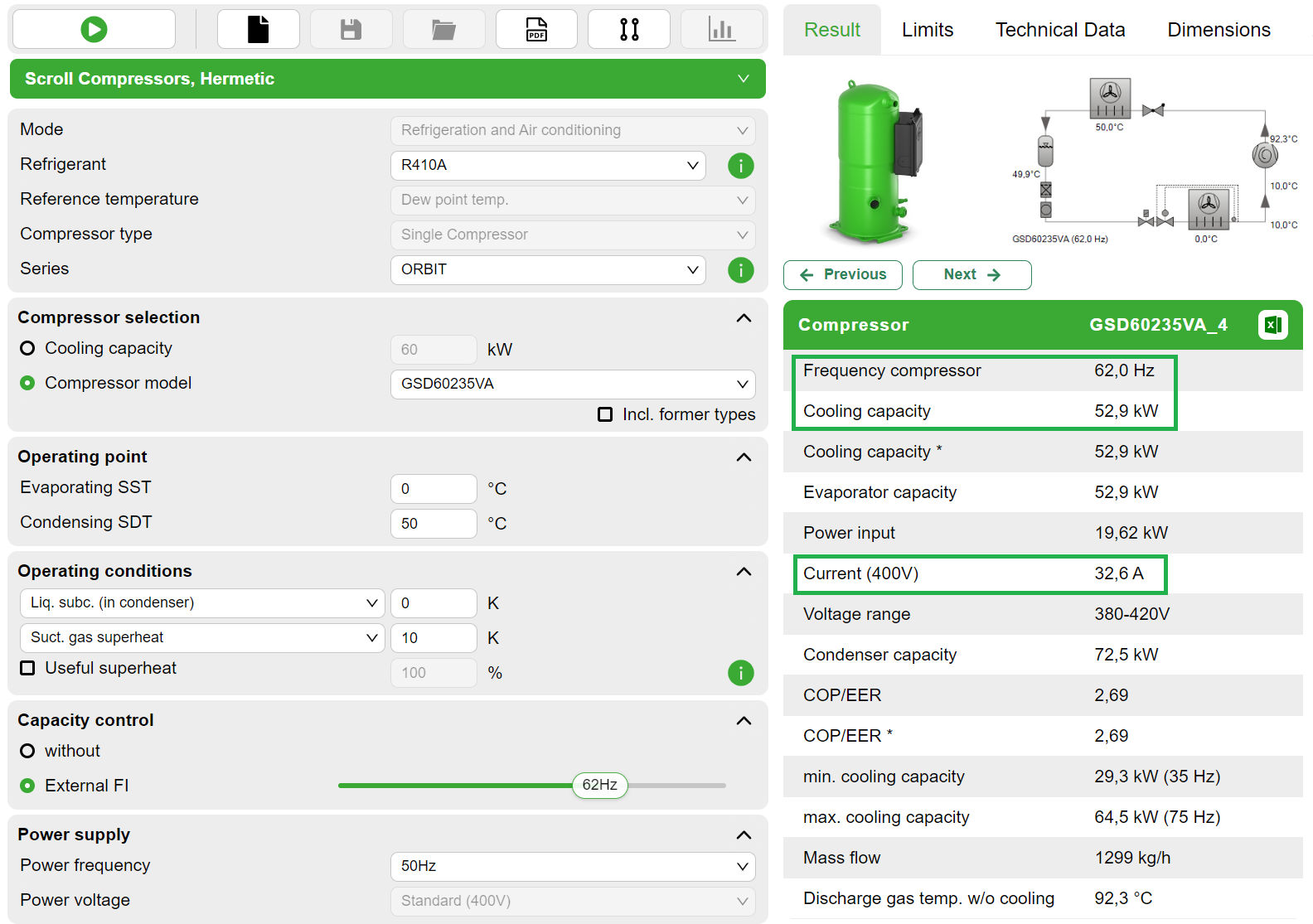

First choose the refrigerant, cooling capacity and operating points, and select "External FI". Then start the calculation by clicking on the button  . The software will then offer two suitable compressors in the range of the maximum operating frequency, each with its standard motor (Compressor motors). If one of the compressors is chosen, the software indicates frequency, cooling capacity and current consumption (voltage):

. The software will then offer two suitable compressors in the range of the maximum operating frequency, each with its standard motor (Compressor motors). If one of the compressors is chosen, the software indicates frequency, cooling capacity and current consumption (voltage):

By gradually increasing the operating frequency (slider at "External FI"), the maximum operating frequency for the selected combination of compressor, refrigerant and operating point can be found. For operation above this frequency, the software shows a warning, a special voltage motor may be available (Special voltage motors). The calculation of special voltage motors, however, is not implemented in the Bitzer Software and available on request.

Step 2a: Selecting a Bitzer Varipack frequency inverter

Due to the modular design of the Varipack frequency inverters, a wide range of versions is available – flexible and matching the Bitzer compressors:

See also:

- CP-110: Brochure Varipack - external Bitzer frequency inverters

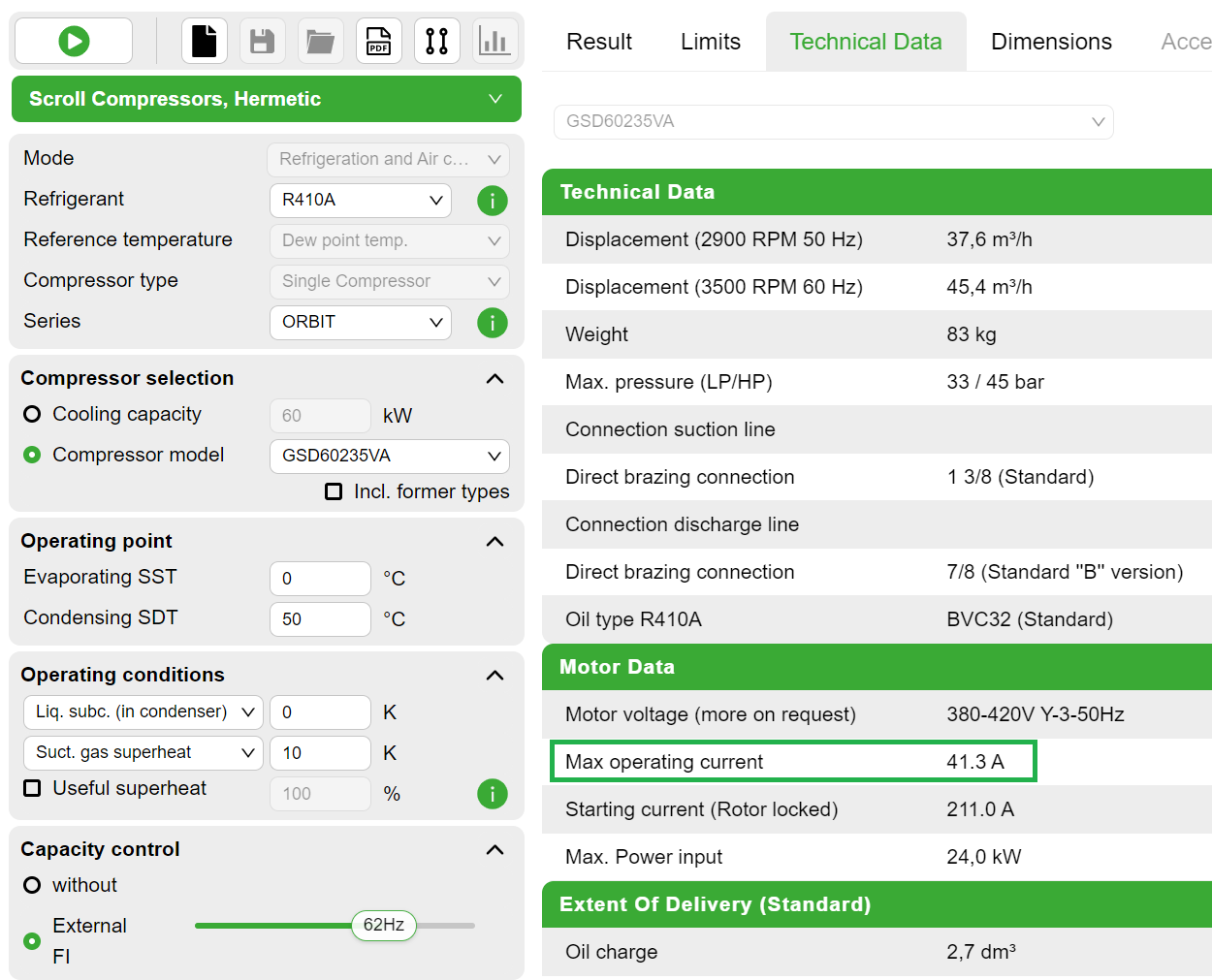

Since the Accessories module in the Bitzer Software is not yet active for scroll compressors, it is necessary to check the maximum operating current of the compressor motor, which must not be exceeded during frequency inverter operation. It is listed in the tab "Technical Data":

In this example, the maximum operating current is 41.3 A, so a Varipack should be chosen with a rated output current of ≥ 41.3 A. According to the product range illustrated above, this would be e.g. the FOY+46 (the middle no. 6 .. 302 in the model designation indicates the rated output current).

The starting characteristics of the compressors have been optimised for Varipack frequency inverters, tested for the different refrigerants, and the results are implemented in the Bitzer software. This ensures a safe compressor start with Varipacks under all conditions.

For further details on the Varipack:

Step 2b: Selecting a frequency inverter of another manufacturer

- Allow at least 10% reserve for operating current

The frequency inverter must be able to continuously supply the operating current to the compressor under all expected operating conditions. At least 10% additional reserve should be planned for, e.g. to compensate for possible undervoltage in the network. If the frequency inverter has limiter functions (which limit the maximum frequency under such circumstances to ensure operational safety), the reserve can possibly be selected smaller.

- Consider overload capacity for compressor start

Additionally, a compensation factor FC for the current during compressor start must be allowed for. For scroll compressors this factor is: FS = 1.2. It is multiplied by the "Max. operating current" that the Bitzer Software indicates for the respective motor in the tab "Technical data" (see below). This maximum current must be within the short-term overload capacity of the frequency inverter, otherwise a larger one is necessary.

multiplied by the compressor-specific compensation factor (for scroll compressors: FS = 1.2)

gives the necessary short-term overload capacity of the frequency inverter.

For Bitzer Varipack frequency inverters (see above), this is already taken into account by design.