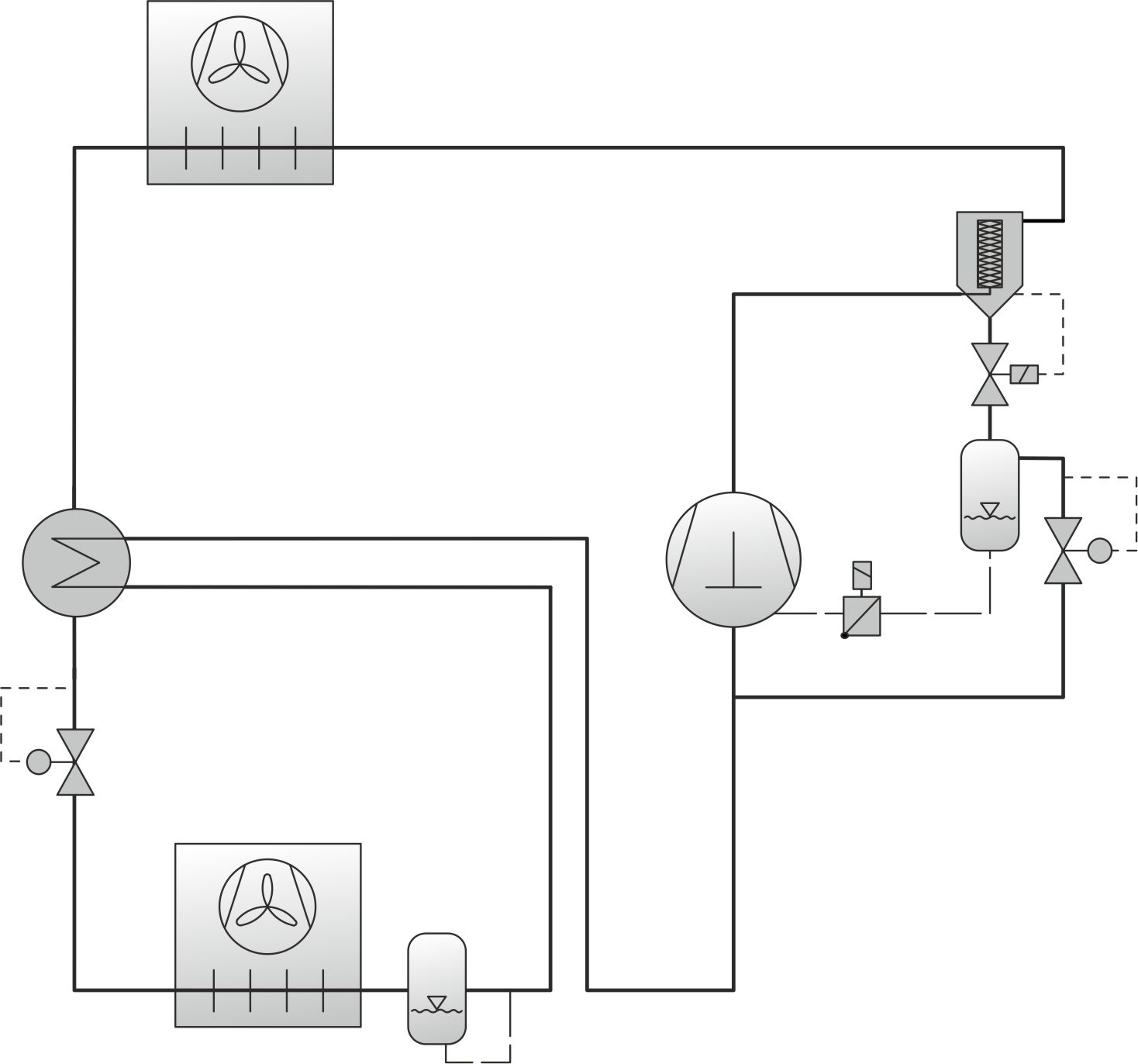

Gustav Lorentzen process (single stage system)

- Single stage compression for a useful temperature level and single stage expansion for medium temperature applications. Without low-temperature compressor stage.

- Standard system design when using R744 in heat pumps.

- No overheating control at the outlet of the evaporator, but operation with flooded evaporator.

- A low-pressure separator must be installed in the suction gas line at the outlet of the evaporator.

- The oil return line must be connected to the bottom of this separator.

- The oil used must be BSG68K from BITZER (a polyalkylene glycol oil).

When this PAG oil is mixed with liquid R744, the oil sinks to a saturation temperature of -32°C at the bottom of the low-pressure separator, where it can be removed. At temperatures below -32°C, however, the oil floats and makes oil return more difficult, especially in defrost mode! - A liquid suction line heat exchanger must be installed so that the minimal amount of liquid R744 contained in the oil, which enters the suction gas line via the oil return line, can be re-evaporated.

This system design is recommended for systems with one evaporator. If several evaporators are to be operated, other system designs are more suitable (see Booster system for medium and low temperature application with flash gas bypass).

The following system diagram is a simplified representation, without the recommended shut-off valve and other control mechanisms recommended above in the oil return line at the low-pressure separator downstream of the evaporator.

1 | Compression |

2-3 | Gas cooling/condensation |

3-4 | Internal heat exchanger/subcooling |

4-5 | Expansion to evaporation temperature |

5-6 | Evaporation |

6-7 | Overheating in the suction gas line |

7-1 | Liquid suction line heat exchanger |