Comparison based on component data

Basically, it is possible to compare refrigerants e.g. via the performance data of compressors in the BITZER Software. For this, operating conditions representative for the planned application have to be chosen. Then, comparisons can be made for refrigeration capacity and efficiency values with different refrigerants in the same compressors or different compressor types. But also here, it has to be considered what is stated in the chapter above on the neutral comparison of refrigerants. The chosen operating conditions can have a significant impact on the results.

Additionally, the characteristics of the compressor will impact the result. It is possible that the compressor is not matching the different refrigerants equally well at these conditions, especially if the thermodynamic behaviour of the selected refrigerants differs significantly. When choosing to compare refrigerants based on performance data from compressors of different basic design, like reciprocating, scroll, screw and turbo compressors, the level of optimisation for the chosen operating conditions might be quite different.

Another influencing factor is the measurement uncertainty of the data. The data may also have been determined on physically different compressors of the same type if they are separated in time. Each measurement, and therefore also the comparison, has uncertainties in the range of a few per cent.

Comparing refrigerants via component data is well suited for refrigerant retrofit calculations. It is also well suited for evaluation of the applicability of results from theoretical comparisons via refrigerant properties in real life systems.

Example data

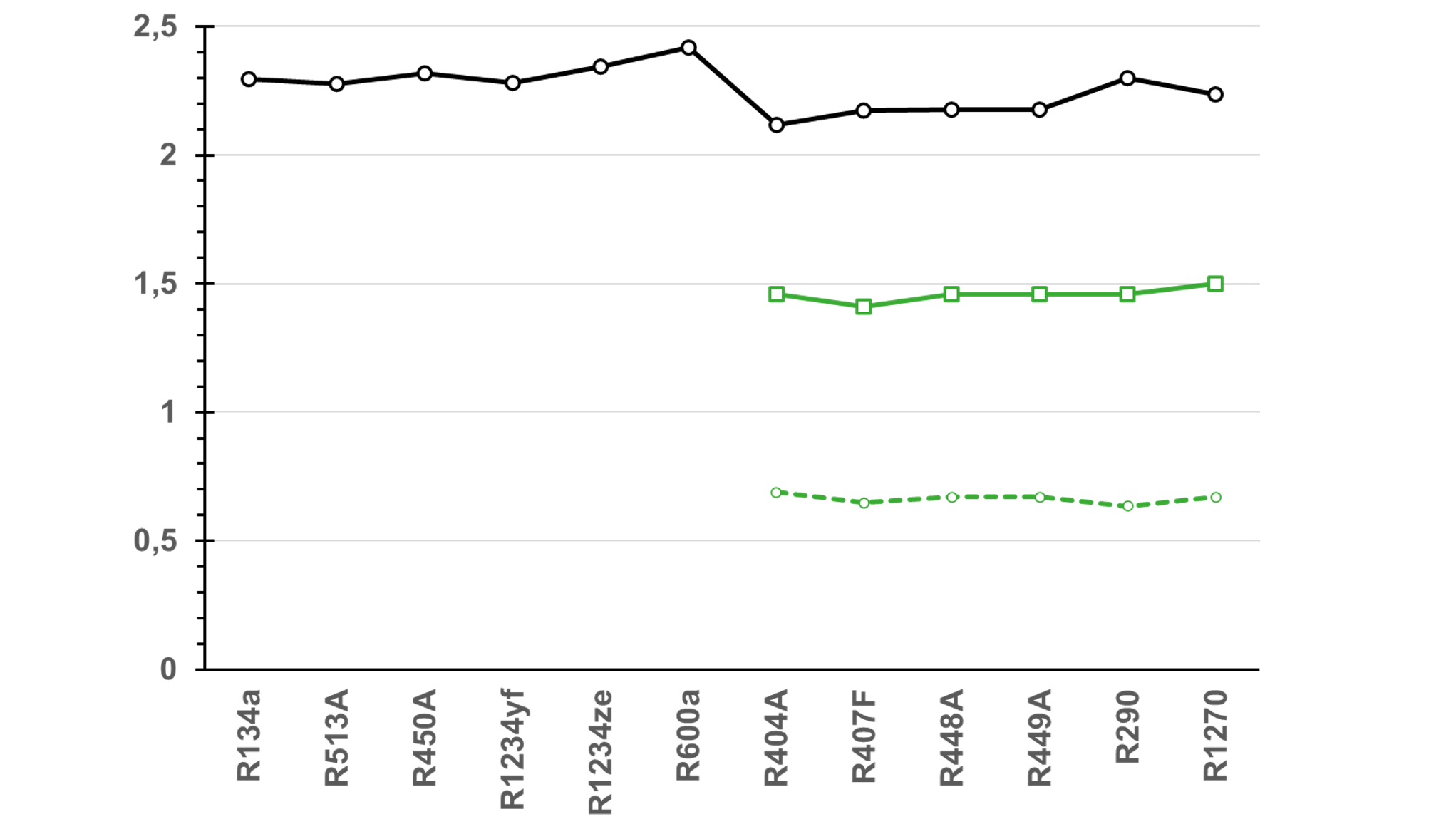

When looking at the theoretical values for the coefficient of performance COP for low temperature refrigeration (shown as solid black line in the figure below), it is noticeable that the refrigerants listed on the left have slightly higher values. However, these refrigerants are usually not applied for low temperature, so no performance data (shown as solid green line) are available for this compressor. The performance data for the compressor are lower than the theoretical data. The quotient of the actual value and the theoretical value is called isentropic efficiency of the compressor (shown as dashed green line). This isentropic efficiency is quite stable around 0.65 to 0.68, which is a proper range for low temperature refrigeration.

The efficiency COP of the compressor varies only little with the refrigerants used. R407F is slightly lower, probably due to the high discharge temperature at this operating point, which heats up the compressor cylinder area significantly. R1270 is slightly higher, which does not correspond exactly to the theoretical value, while R290 does not show the advantage of the theoretical value in the real data. However, the differences are minor. This may well be partly due to the measurement uncertainties mentioned above.

Overall, a very similar comparison result is achieved with real life data and theoretical data, as far as the uncertainty of the data and the compressor design optimisation for the refrigerants allows. This also suggests that the theoretical comparison is a proper and neutral tool for comparisons, especially if no compressors are available that are designed and suited equally well for all candidates to be compared.

Bringing the slight efficiency benefits of the refrigerants listed on the left, e.g. R600a, to real life, needs a compressor optimised for evaporation, i.e. suction pressure below ambient pressure and for higher pressure ratio with less power consumption of the motor. For these refrigerants, the target application for this compressor is rather mid temperature refrigeration or even higher evaporation temperatures.