- myBITZER

- BITZER SOFTWARE

-

ePARTS

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

- Documentation

- Contact

- Germany (de)

-

Germany (de)

-

Please select country and language:

-

Europe

- Austria / de

- Belarus / en

- Belgium / fr

- Bosnia-Herzegovina / en

- Bulgaria / en

- Croatia / en

- Cyprus / en

- Czech Republic / en

- Denmark / en

- Denmark / dk-en

- Estonia / en

- Finland / en

- France / fr

- Germany / de

- Greece / en

- Hungary / en

- Iceland / en

- Ireland / en

- Italy / it

- Latvia / en

- Lithuania / en

- Luxembourg / fr

- Malta / en

- Netherlands / en

- Norway / en

- Poland / en

- Portugal / pt

- Romania / en

- Russia / ru

- Serbia & Montenegro / en

- Slovakia / en

- Slovenia / en

- Spain / es

- Sweden / en

- Switzerland / de

- Turkey / en

- Ukraine / en

- United Kingdom / en

-

America

- Argentina / es

- Barbados / en

- Belize / en

- Bolivien / es

- Bonaire, Sint Eustatius and Saba / en

- Brazil / pt-br

- Canada / en

- Canada / fr

- Caribbean / en

- Chile / es

- Colombia / es

- Costa Rica / es

- Cuba / es

- Curacao / en

- Dominican Republic / es

- Ecuador / es

- El Salvador / es

- Grenada / es

- Guatemala / es

- Haiti / fr

- Honduras / es

- Jamaika / en

- Mexico / es

- Netherlands Antilles / en

- Nicaragua / es

- Panama / es

- Paraguay / es

- Peru / es

- Puerto Rico / en

- Puerto Rico / es

- Sint Maarten (Dutch part) / en

- Trinidad & Tobago / en

- U.S.A. / us

- Venezuela / es

-

Asia

- Bahrain / en

- Bangladesh / en

- Brunei / en

- China / zh

- Hong Kong SAR of China / en

- India / in-en

- India / en

- Indonesia / en

- Iran / en

- Israel / en

- Japan / ja

- Jordan / en

- Kuwait / en

- Lebanon / en

- Malaysia / en

- Maldives / en

- Myanmar / en

- Oman / en

- Pakistan / en

- Philippines / en

- Qatar / en

- Saudi Arabia / en

- Singapore / en

- South Korea / ko

- Sri Lanka / en

- Syria / en

- Thailand / en

- U.A.E. / en

- Vietnam / en

- Yemen / en

-

Africa

- Algeria / fr

- Angola / pt

- Botswana / en

- Cameroon / fr

- Cameroon / en

- Democratic Republic of Congo (DRC) / fr

- Djibouti / fr

- Egypt / en

- Equatorial Guinea / es

- Equatorial Guinea / pt

- Equatorial Guinea / fr

- Ethiopia / en

- Ghana / en

- Kenya / en

- Lesotho / en

- Libya / en

- Madagascar / fr

- Malawi / en

- Mauritius / en

- Morocco / en

- Mozambique / pt

- Namibia / en

- Nigeria / en

- Reunion / fr

- Senegal / fr

- Seychelles / en

- Seychelles / fr

- South Africa / en

- Sudan / en

- Swaziland / en

- Tanzania / en

- Tunisia / en

- Uganda / en

- Zambia / en

- Zimbabwe / en

-

Australia

-

- Australia / en

- New Zealand / en

-

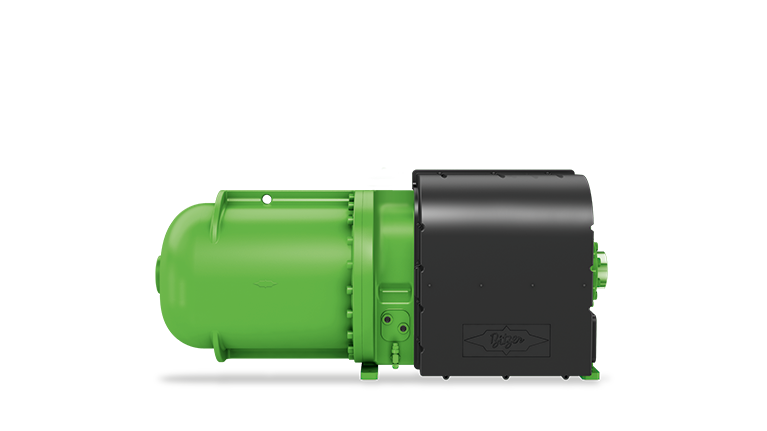

CSV.2 & CSV.3 SERIES

On the notepadThe CSV is the BITZER compact screw compressor series with integrated frequency inverter for best-in-class seasonal efficiency. The built-in frequency inverter makes it possible to achieve a very accurate system temperature and load profile by means of a very wide capacity modulation range. By integrating the frequency inverter and IQ functionality in the compressor, the CSV offers a new level of compactness and user-friendliness. This simplifies the system integration and enables a compact and cost-effective system design.

Refrigerants

- R134a, non-flammable, A1

- R513A, R450A, non-flammable, A1

- R1234ze(E), R1234yf, flammable, A2L

Product range

- 5 models from 464 to 1206 m³/h

Certifications

- CE

- EAC

- UL

Applications

- A/C chillers

- with and without heat recovery

- Reversible A/C chillers for cooling and heating

- Process chillers for HT / MT / LT application

- with and without heat recovery

- Heat pumps

- space heating

- process heating

Industry sectors

- Building equipment industry

- Automotive and mechanical engineering industry

- Food and beverages industry

- Injection moulding industry

- Chemical and pharmaceutical industry

- Marine and offshore industry

- And many more

Highlights

- Best-in-class seasonal efficiency

- Wide-capacity modulation range

- Enables OEM system manufacturer to fulfil the highest international chiller efficiency standards

- On-board IQ functionality with protection, monitoring, data log and communication

- Extremely compact design with the smallest footprint in class

Integrated frequency inverter

- Specially developed for the CSV series

- Extremely compact and reliable due to refrigerant cooling

- Automatic soft-start function

Product versions

- CSVH: designed for air cooled A/C and process chillers and heat pumps

- CSVW: designed for water cooled A/C and process chillers and air cooled systems with lower condensing temperatures

Mechanical design

- Proven design features taken from CSH/CSW

- Specially designed very quick acting rotor profiles and bearings

- Automatic Vᵢ adaptation

- High-efficiency oil separator

Motor

- Special very quick acting suction gas cooled design

- Industry-leading full and part-load motor efficiency

- Wide speed range – up to 8000 rpm (CSV.26)

- Integrated motor temperature monitoring

Reduced life cycle costs

- Best-in-class seasonal efficiency in wide application range

- Advanced compressor protection by active application monitoring

- Low maintenance costs due to service-friendly design

- Global Service network for quick spare parts availability all over the world

Reduced development costs

- Extensive documentation and BITZER know-how for technical support

- Wide range of matching accessories

- easily calculated and selected via BITZER SOFTWARE

- Simple installation

- Frequency inverter, motor, sensors, and controller prewired and tested ex-factory

- Minimal effort for external cabling needed

- Low weight and small footprint for easy system integration

Monitored operation

- Enhanced operation monitoring

- 3 stage warning and alarm management close to the application limits before shut-off

- Flexible user settings for adapting/optimising the system

Flexibility and reliability

- Wide application range enables flexible use

- In a wide range of system configurations

- For mechanical capacity control or variable-speed drive

- Wide range of refrigerants

- Perfect match of refrigerant and compressor

- Applicable under different international refrigerant regulations

- All compressors are 100% factory-tested and preparameterized

Compressor-related accessories

- Wide range of suction and discharge bushings and discharge gas shut-off valves

- Adaptor and shut-off valve for economizer connection

- Adaptor for oil return from flooded/falling-film evaporators

- Matching line reactors and RFI filters

Communication

- BEST interface converter

- Bluetooth

System-related accessories

- Secondary oil separators for use with flooded/falling-film evaporators

- vertical secondary oil separators: OAF series

- Liquid receivers

- horizontal liquid receivers: F series

- vertical liquid receivers: FS series

- Oil cooler

- OL series (air cooled) / - OW series (water cooled)

-

Features

Highlights

- Best-in-class seasonal efficiency

- Wide-capacity modulation range

- Enables OEM system manufacturer to fulfil the highest international chiller efficiency standards

- On-board IQ functionality with protection, monitoring, data log and communication

- Extremely compact design with the smallest footprint in class

Integrated frequency inverter

- Specially developed for the CSV series

- Extremely compact and reliable due to refrigerant cooling

- Automatic soft-start function

Product versions

- CSVH: designed for air cooled A/C and process chillers and heat pumps

- CSVW: designed for water cooled A/C and process chillers and air cooled systems with lower condensing temperatures

Mechanical design

- Proven design features taken from CSH/CSW

- Specially designed very quick acting rotor profiles and bearings

- Automatic Vᵢ adaptation

- High-efficiency oil separator

Motor

- Special very quick acting suction gas cooled design

- Industry-leading full and part-load motor efficiency

- Wide speed range – up to 8000 rpm (CSV.26)

- Integrated motor temperature monitoring

-

Benefits

Reduced life cycle costs

- Best-in-class seasonal efficiency in wide application range

- Advanced compressor protection by active application monitoring

- Low maintenance costs due to service-friendly design

- Global Service network for quick spare parts availability all over the world

Reduced development costs

- Extensive documentation and BITZER know-how for technical support

- Wide range of matching accessories

- easily calculated and selected via BITZER SOFTWARE

- Simple installation

- Frequency inverter, motor, sensors, and controller prewired and tested ex-factory

- Minimal effort for external cabling needed

- Low weight and small footprint for easy system integration

Monitored operation

- Enhanced operation monitoring

- 3 stage warning and alarm management close to the application limits before shut-off

- Flexible user settings for adapting/optimising the system

Flexibility and reliability

- Wide application range enables flexible use

- In a wide range of system configurations

- For mechanical capacity control or variable-speed drive

- Wide range of refrigerants

- Perfect match of refrigerant and compressor

- Applicable under different international refrigerant regulations

- All compressors are 100% factory-tested and preparameterized

- Video

-

Accessories

Compressor-related accessories

- Wide range of suction and discharge bushings and discharge gas shut-off valves

- Adaptor and shut-off valve for economizer connection

- Adaptor for oil return from flooded/falling-film evaporators

- Matching line reactors and RFI filters

Communication

- BEST interface converter

- Bluetooth

System-related accessories

- Secondary oil separators for use with flooded/falling-film evaporators

- vertical secondary oil separators: OAF series

- Liquid receivers

- horizontal liquid receivers: F series

- vertical liquid receivers: FS series

- Oil cooler

- OL series (air cooled) / - OW series (water cooled)

Technical Information*

Brochures*

Operating instructions*

*For further documentation please choose Product Type

Products

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

Technical Data OPEN IN SOFTWARE TO DOCUMENTATION

* Minimum/maximum displacement in m³/h