- myBITZER

- BITZER SOFTWARE

-

ePARTS

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

ePARTS makes finding the appropriate spare parts for our products fast and easy. The parts are listed according to the model range and appear as a simple zoomable expanded-view drawing. The software is free of charge. As a direct BITZER customer registered at myBITZER, you benefit from additional advanced features – for example, the ability to view online prices of individual spare parts.

- Documentation

- Contact

- GB / en

-

GB / en

- Back

-

Please select country and language:

-

Europe

- Back

- Austria / de

- Belarus / en

- Belgium / fr

- Bosnia-Herzegovina / en

- Bulgaria / en

- Croatia / en

- Cyprus / en

- Czech Republic / en

- Denmark / en

- Denmark / dk-en

- Estonia / en

- Finland / en

- France / fr

- Germany / de

- Greece / en

- Hungary / en

- Iceland / en

- Ireland / en

- Italy / it

- Latvia / en

- Lithuania / en

- Luxembourg / fr

- Malta / en

- Netherlands / en

- Norway / en

- Poland / en

- Portugal / pt

- Romania / en

- Russia / ru

- Serbia & Montenegro / en

- Slovakia / en

- Slovenia / en

- Spain / es

- Sweden / en

- Switzerland / de

- Turkey / en

- Ukraine / en

- United Kingdom / en

-

America

- Back

- Argentina / es

- Barbados / en

- Belize / en

- Bolivien / es

- Bonaire, Sint Eustatius and Saba / en

- Brazil / pt-br

- Canada / en

- Canada / fr

- Caribbean / en

- Chile / es

- Colombia / es

- Costa Rica / es

- Cuba / es

- Curacao / en

- Dominican Republic / es

- Ecuador / es

- El Salvador / es

- Grenada / es

- Guatemala / es

- Haiti / fr

- Honduras / es

- Jamaika / en

- Mexico / es

- Netherlands Antilles / en

- Nicaragua / es

- Panama / es

- Paraguay / es

- Peru / es

- Puerto Rico / en

- Puerto Rico / es

- Sint Maarten (Dutch part) / en

- Trinidad & Tobago / en

- U.S.A. / us

- Venezuela / es

-

Asia

- Back

- Bahrain / en

- Bangladesh / en

- Brunei / en

- China / zh

- Hong Kong SAR of China / en

- India / in-en

- India / en

- Indonesia / en

- Iran / en

- Israel / en

- Japan / ja

- Jordan / en

- Kuwait / en

- Lebanon / en

- Malaysia / en

- Maldives / en

- Myanmar / en

- Oman / en

- Pakistan / en

- Philippines / en

- Qatar / en

- Saudi Arabia / en

- Singapore / en

- South Korea / ko

- Sri Lanka / en

- Syria / en

- Thailand / en

- U.A.E. / en

- Vietnam / en

- Yemen / en

-

Africa

- Back

- Algeria / fr

- Angola / pt

- Botswana / en

- Cameroon / fr

- Cameroon / en

- Democratic Republic of Congo (DRC) / fr

- Djibouti / fr

- Egypt / en

- Equatorial Guinea / es

- Equatorial Guinea / pt

- Equatorial Guinea / fr

- Ethiopia / en

- Ghana / en

- Kenya / en

- Lesotho / en

- Libya / en

- Madagascar / fr

- Malawi / en

- Mauritius / en

- Morocco / en

- Mozambique / pt

- Namibia / en

- Nigeria / en

- Reunion / fr

- Senegal / fr

- Seychelles / en

- Seychelles / fr

- South Africa / en

- Sudan / en

- Swaziland / en

- Tanzania / en

- Tunisia / en

- Uganda / en

- Zambia / en

- Zimbabwe / en

-

Australia

- Back

- Australia / en

- New Zealand / en

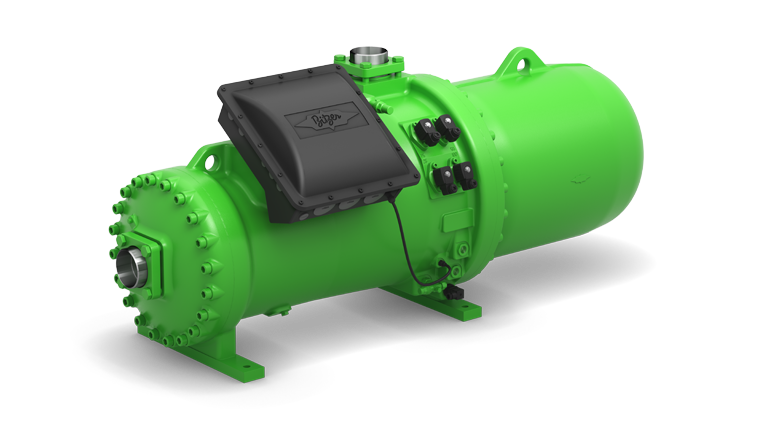

CS PRO series for process cooling (R290, R1270)

CS PRO series for process cooling (R290, R1270)

The compact screw compressors in this CS PRO design are designed to operate with the natural, low-GWP refrigerants propane (R290) and propene (R1270).

These models were primarily developed for process cooling applications with and without heat recovery and allow for liquid outlet temperatures from roughly -25°C up to +70°C. The CS PRO series differs from the standard CS series due to its special electrical accessories, oil charge, safety devices and internal lubrication system.

As propane and propene are flammable refrigerants in the A3 safety class, these compressors are only available to OEM contractors who have experience working with flammable refrigerants.

Refrigerant

- Natural hydrocarbon refrigerants with low global warming potential

- R290 & R1270, A3 safety class (flammable)

Product range

- Models from 137 to 1120 m³/h at 50 Hz

Special requirements

- Upon request, the CS PRO series can be supplied in a range of ATEX designs for installation in zones with explosion protection requirements.

General applications

- Process liquid chillers for high, medium and low-temperature applications

- e.g.: Compliance with minimum efficiency requirements under EU 2015/1095

- For industry-leading SEPR (Seasonal Efficiency Performance Ratio) values

- With and without heat recovery

- Low and medium-temperature heat pumps for liquid outlet temperatures up to approx. +70°C

Sectors

- Building services industry

- Automotive and mechanical engineering industry

- Food and beverage

- Injection moulding industry

- Chemical and pharmaceutical industry

- Shipping and offshore industry

- And many more …

- CE

- Classification: ‘No sources of ignition in normal operation’

- In normal operation with no faults, the product and its components contain no sources of ignition that could ignite class A3 flammable refrigerants from Group IIA under IEC 60079.

- Classification: ‘Durably technically tight’

- The product has increased tightness pursuant to EN 1127-1 and is therefore considered durably technically tight.

- If the product contains flammable gases, this classification means that no ATEX zone has to be assumed around the component.

- EAC

Product versions

- The compact screw compressors in this CS PRO design are particularly suited for use:

- with natural hydrocarbon refrigerants with low global warming potential like propane (R290) and propene (R1270).

- for low, medium and high-temperature process cooling applications with and without heat recovery

-

- Liquid temperatures for process coolers in accordance with Regulation (EU) 2015/1095:

- LT -25°C

- MT -8°C

- HT +7°C

- Liquid temperatures for process coolers in accordance with Regulation (EU) 2015/1095:

- for low and medium-temperature heat pumps with a liquid outlet temperature of up to approx. +70°C

Reduced life cycle costs

- Outstanding efficiency in wide application range

- Long lifetime due to high robustness and low-vibration design

- Low maintenance costs due to service-friendly design

- Global Service network for quick spare part availability all over the world

Reduced development costs

- Extensive documentation and BITZER know-how for technical support

- Wide range of matching accessories

Flexibility and reliability

- Wide application range enables flexible use

- in a wide range of system configurations

- with mechanical capacity control or variable-speed drive

- Optimized for operation with the natural low-GWP hydrocarbon refrigerants Propane (R290) and Propylene (R1270)

- Perfect coordination of refrigerant and compressor

- Hydrocarbon refrigerants are not subject to the European F-Gas Regulation EU 2024/573 and REACH Regulation 1907/2006 (PFAS)

- All compressors are 100% factory-tested

Compressor-related accessories

- Wide range of motors for different power supply voltages

- Wide range of suction and discharge bushings and discharge gas shut-off valves

- Adaptor and shut-off valve for economiser connection

- SE-i1 compressor protection device for advanced compressor protection, monitoring and data log

System-related accessories

- Liquid receivers for use with hydrocarbon refrigerants

- horizontal liquid receivers: F..P series

- vertical liquid receivers: FS..P series

-

Certifications

- CE

- Classification: ‘No sources of ignition in normal operation’

- In normal operation with no faults, the product and its components contain no sources of ignition that could ignite class A3 flammable refrigerants from Group IIA under IEC 60079.

- Classification: ‘Durably technically tight’

- The product has increased tightness pursuant to EN 1127-1 and is therefore considered durably technically tight.

- If the product contains flammable gases, this classification means that no ATEX zone has to be assumed around the component.

- EAC

-

Features

Product versions

- The compact screw compressors in this CS PRO design are particularly suited for use:

- with natural hydrocarbon refrigerants with low global warming potential like propane (R290) and propene (R1270).

- for low, medium and high-temperature process cooling applications with and without heat recovery

-

- Liquid temperatures for process coolers in accordance with Regulation (EU) 2015/1095:

- LT -25°C

- MT -8°C

- HT +7°C

- Liquid temperatures for process coolers in accordance with Regulation (EU) 2015/1095:

- for low and medium-temperature heat pumps with a liquid outlet temperature of up to approx. +70°C

- The compact screw compressors in this CS PRO design are particularly suited for use:

-

Benefits

Reduced life cycle costs

- Outstanding efficiency in wide application range

- Long lifetime due to high robustness and low-vibration design

- Low maintenance costs due to service-friendly design

- Global Service network for quick spare part availability all over the world

Reduced development costs

- Extensive documentation and BITZER know-how for technical support

- Wide range of matching accessories

Flexibility and reliability

- Wide application range enables flexible use

- in a wide range of system configurations

- with mechanical capacity control or variable-speed drive

- Optimized for operation with the natural low-GWP hydrocarbon refrigerants Propane (R290) and Propylene (R1270)

- Perfect coordination of refrigerant and compressor

- Hydrocarbon refrigerants are not subject to the European F-Gas Regulation EU 2024/573 and REACH Regulation 1907/2006 (PFAS)

- All compressors are 100% factory-tested

-

Accessories

Compressor-related accessories

- Wide range of motors for different power supply voltages

- Wide range of suction and discharge bushings and discharge gas shut-off valves

- Adaptor and shut-off valve for economiser connection

- SE-i1 compressor protection device for advanced compressor protection, monitoring and data log

System-related accessories

- Liquid receivers for use with hydrocarbon refrigerants

- horizontal liquid receivers: F..P series

- vertical liquid receivers: FS..P series